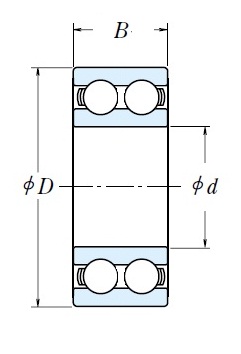

Basic Dimensions | Design |

||

|---|---|---|---|

d (mm) | D (mm) | B (mm) | |

10 | 30 | 14 | 4200 ATN |

12 | 32 | 14 | 4201 ATN |

12 | 37 | 14 | 4301 ATN |

15 | 35 | 14 | 4202 ATN |

15 | 42 | 17 | 4302 ATN |

17 | 40 | 16 | 4203 ATN |

17 | 47 | 19 | 4303 ATN |

20 | 47 | 18 | 4204ATN |

20 | 52 | 21 | 4304 ATN |

25 | 52 | 18 | 4205 ATN |

25 | 62 | 24 | 4305 ATN |

30 | 62 | 20 | 4206 ATN |

30 | 72 | 27 | 4306 ATN |

35 | 72 | 23 | 4207 ATN |

35 | 80 | 31 | 4307 ATN |

40 | 80 | 23 | 4208 ATN |

40 | 90 | 33 | 4308 ATN |

45 | 85 | 23 | 4209 ATN |

45 | 100 | 36 | 4309 ATN |

50 | 90 | 23 | 4210 ATN |

50 | 110 | 40 | 4310 ATN |

55 | 100 | 25 | 4211 ATN |

55 | 120 | 43 | 4311 ATN |

60 | 110 | 28 | 4212 ATN |

60 | 130 | 46 | 4312 ATN |

65 | 120 | 31 | 4213 ATN |

65 | 140 | 48 | 4313 ATN |

70 | 125 | 31 | 4214 ATN |

70 | 150 | 51 | 4314 ATN |

75 | 130 | 31 | 4215 ATN |

75 | 160 | 55 | 4315 ATN |

80 | 140 | 33 | 4216 ATN |

85 | 150 | 36 | 4217 ATN |

90 | 160 | 40 | 4218 ATN |

100 | 180 | 46 | 4220 ATN |

Double Row Deep Groove Ball Bearing

The Double Row Deep Groove Ball Bearing is a highly versatile and robust bearing solution designed for applications that demand higher load capacities than traditional single row deep groove ball bearings. These bearings are a cornerstone of modern industrial machinery, offering reliable performance, reduced friction, and exceptional durability in various demanding environments.

What is a Double Row Deep Groove Ball Bearing?

A Double Row Deep Groove Ball Bearing fundamentally consists of an inner ring, an outer ring, two rows of steel balls, and two cages. Unlike single row bearings, which have one set of balls and raceways, the double row design incorporates two distinct raceways, allowing for a significantly increased number of rolling elements. This structural difference enables them to handle greater radial and axial loads, making them ideal for heavier duty applications. The raceway grooves are deep and curvilinear, with a radius only slightly larger than that of the balls, ensuring optimal ball conformity and load distribution.

What are the Applications for Double Row Deep Groove Ball Bearings?

The enhanced load-carrying capacity and rigidity of Double Row Deep Groove Ball Bearings make them suitable for a wide array of applications across various industries. Their ability to manage both radial and axial loads in both directions, along with good high-speed capabilities, positions them as a preferred choice in demanding machinery. Common applications include:

- Industrial Gearboxes and Transmissions: Supporting shafts and gears under varying load conditions.

- Pumps and Compressors: Ensuring reliable operation under high radial loads and varying speeds.

- Agricultural Machinery: Handling heavy loads and harsh operating environments.

- Construction Equipment: Providing robust support in heavy-duty machinery.

- Electric Motors and Generators: Where higher load capacity is required compared to single-row bearings.

- Material Handling Equipment: Conveyor systems and other machinery requiring smooth and efficient material movement.

- Mining Machinery: Withstanding large radial and axial loads in mineral processing and powder equipment.

- Automotive Industry: In specific components requiring enhanced durability and load support.

- Special Vehicles: Providing robust bearing solutions in various specialized transport applications.

- Automation Production: Essential components in automated systems where reliability is paramount.

Types of Double Row Deep Groove Ball Bearings

While the core design principle remains consistent, Double Row Deep Groove Ball Bearings are primarily categorized by their specific series and design features. The most common types include:

- Standard Double Row Deep Groove Ball Bearings (e.g., 4200A, 4300A series): These are the foundational types, designed for general industrial use. They often feature polyamide (PA66) cages for good performance at higher temperatures.

- Open Bearings: Bearings without seals or shields, allowing for external lubrication and inspection.

- Sealed/Shielded Bearings: Although less common in standard double row deep groove designs compared to single row, some variants may come with shields (ZZ) or seals (2RS) for protection against contaminants and retention of lubricant. These are often application-specific or custom designs.

- Variants for Specific Conditions: Depending on the manufacturer, special variants might exist for high-temperature environments, specific lubrication requirements, or those designed to offer reduced noise and vibration.

Mechanics of Different Types of Double Row Deep Groove Ball Bearings

The fundamental mechanics of Double Row Deep Groove Ball Bearings revolve around the principle of rolling friction. Here’s a brief introduction to their mechanics:

The bearing consists of two concentric rings (inner and outer) with deep, circular arc raceways. Between these raceways are two sets of precision-ground steel balls, separated and guided by cages. When a radial load is applied, the load is distributed across both rows of balls, and the contact points between the balls and raceways deform slightly, creating an elliptical contact area. This distribution across two rows significantly increases the bearing’s ability to handle heavier loads compared to a single-row design.

What Industries Use Double Row Deep Groove Ball Bearings?

Double Row Deep Groove Ball Bearings are integral to a wide range of industries due to their versatility and robustness. Some key industries include:

- Heavy Industrial Manufacturing: Used in machinery like rolling mills, crushers, and large motors.

- Automotive Industry: In various driveline components, transmissions, and heavy vehicles.

- Agricultural Sector: For equipment such as tractors, harvesters, and irrigation systems.

- Construction Industry: In excavators, bulldozers, and other heavy construction machinery.

- Power Generation: Within turbines, generators, and auxiliary equipment.

- Mining and Quarrying: Essential for robust operation in conveyor systems, crushers, and screening equipment.

- Food and Beverage Processing: In machinery requiring hygienic and reliable operation, often utilizing stainless steel variants.

- Material Handling: Cranes, forklifts, and automated warehousing systems.

- Pulp and Paper: In paper machines and processing equipment.

- Steel Industry: In steel production machinery, which operates under extreme loads and temperatures.

Buy Genuine Double Row Deep Groove Ball Bearing from www.bearings.co.th

At www.bearings.co.th, we are committed to providing only genuine Double Row Deep Groove Ball Bearings from world-renowned manufacturers. As authorized distributors, we guarantee the authenticity and quality of every product, ensuring optimal performance and longevity for your critical applications.

Product Information & Facts:

Our extensive inventory of Deep Groove Ball Bearings, including double row variants, features a wide range of sizes and specifications to meet diverse industrial requirements. You can browse by inside diameter, outside diameter, and width to find the perfect fit for your machinery.

Key Features of our Double Row Deep Groove Ball Bearings:

- Enhanced Load Capacity: Designed to carry significantly higher radial and axial loads compared to single-row bearings.

- Increased Rigidity: Provides greater stiffness for improved operational precision and stability.

- Bidirectional Axial Load Support: Capable of handling axial forces in both directions, making them highly versatile.

- High-Speed Capability: Optimized for high rotational speeds with low friction and noise.

- Durability and Long Service Life: Manufactured from high-quality bearing steel for extended operational life.

- Reduced Maintenance: Simple design and robust construction contribute to lower maintenance requirements.

Brands Famous for Reliable Double Row Deep Groove Ball Bearing

Several global brands are renowned for producing high-quality and reliable Double Row Deep Groove Ball Bearings. These manufacturers are leaders in bearing technology, known for their precision engineering, advanced materials, and rigorous quality control. Some of the most famous brands include:

- Timken

- NSK

- NIS

As authorized distributors, www.bearings.co.th proudly supply genuine Double Row Deep Groove Ball Bearings from these world-leading brands. Our commitment ensures that you receive only authentic products with full manufacturer warranties and technical support.

Specifically, from these websites, we are authorized distributors for:

- Timken

- NSK

- NIS

We focus on providing the most reliable and high-performance Double Row Deep Groove Ball Bearings to meet the rigorous demands of your industrial machinery. Contact us to verify specific brand availability or for expert assistance in selecting the ideal bearing for your application.