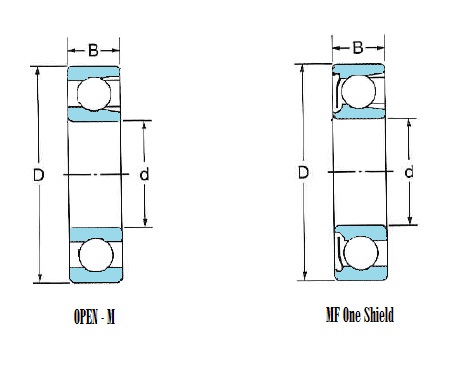

Basic Dimensions | Design |

||

|---|---|---|---|

d (mm) | D (mm) | B (mm) | |

50 | 90 | 11 | 110M |

65 | 115 | 14 | 113M |

85 | 145 | 18 | 117M |

100 | 160 | 28 | 120M |

100 | 160 | 28 | 120MF |

120 | 190 | 32 | 124M |

120 | 190 | 32 | 124MF |

130 | 205 | 34 | 126M |

130 | 205 | 34 | 126MF |

140 | 220 | 36 | 128M |

140 | 220 | 36 | 128MF |

160 | 250 | 40 | 132M |

160 | 250 | 40 | 132MF |

Single Row Deep Groove Ball Bearings – Heavy Duty

What are Single Row Deep Groove Ball Bearings – Heavy Duty?

Single Row Deep Groove Ball Bearings – Heavy Duty are specialized variants of the most widely used rolling bearings, engineered to withstand exceptionally high radial and axial loads in demanding industrial environments. Characterized by their deep raceway grooves, these bearings provide a robust solution for applications where standard bearings might fail due to intense stress, shock loads, or continuous heavy operation. Their design ensures low friction and the ability to operate at high speeds, offering both efficiency and superior durability. Typically constructed from high-grade bearing steel like GCR15 (AISI 52100) for rings and balls, and often featuring robust cages, these heavy-duty bearings are built for longevity and reliable performance under severe conditions. They are available in various configurations, including open, shielded (ZZ), or sealed (RS, 2RS) designs, offering protection against contaminants.

Applications for Single Row Deep Groove Ball Bearings – Heavy Duty

The robust nature of Single Row Deep Groove Ball Bearings – Heavy Duty makes them indispensable in a wide array of high-stress applications across numerous industries. Their capacity to handle significant radial and axial forces simultaneously, coupled with their low frictional resistance and high-speed capability, makes them ideal for:

- Industrial Machinery: Used extensively in heavy industrial motors, large gearboxes, and machine tool gearboxes where reliability under continuous operation is critical.

- Automotive & Transportation: Essential in heavy vehicle suspension and transmission systems, as well as wheel bearings for trucks and buses, ensuring smooth and safe operation.

- Construction & Agricultural Equipment: Key components in tractors, excavators, and other heavy equipment, supporting vital rotational and transmission mechanisms that endure harsh conditions.

- Material Handling: Found in heavy-duty conveyor systems and lifting equipment, managing large loads and continuous operation.

- Mining & Quarrying: Crucial for machinery operating in abrasive and high-impact environments, such as crushers and screening equipment.

- Energy & Power Generation: Employed in turbines, generators, and other power machinery that demand high load capacity and continuous operation.

- Steel Production & Metal Industries: Withstand high temperatures and heavy loads in rolling mills and other metal processing equipment.

Types of Single Row Deep Groove Ball Bearings – Heavy Duty

While the core design remains consistent, Single Row Deep Groove Ball Bearings – Heavy Duty can come in several types optimized for specific demanding scenarios:

- Standard Heavy-Duty: Enhanced versions of conventional deep groove bearings with stronger materials and larger internal clearances (like C3, C4, C5) to accommodate thermal expansion under heavy loads.

- Maximum Type Bearings: Designed with filling slots that allow for a greater number of balls, significantly increasing their radial load-carrying capacity. These are particularly suited for applications with predominantly radial heavy loads.

- Sealed and Shielded Heavy-Duty: Feature robust seals (RS, 2RS) or shields (Z, ZZ) to protect against severe contamination, crucial in dirty or wet heavy-duty environments, ensuring extended lubricant life and reduced maintenance.

- Hybrid Heavy-Duty: Incorporate ceramic balls for applications requiring higher speeds, reduced friction, electrical insulation, and superior performance in extreme temperatures.

- Stainless Steel Heavy-Duty: Offer enhanced corrosion resistance for demanding environments exposed to moisture, chemicals, or specific wash-down requirements.

Mechanics of Different Types of Single Row Deep Groove Ball Bearings – Heavy Duty

The fundamental mechanics involve the rolling motion of spherical balls between deep, circular raceways on both inner and outer rings, converting sliding friction into rolling friction. This enables smooth, low-torque rotation.

- Standard Heavy-Duty: The deep raceway grooves allow these bearings to accommodate both significant radial loads (perpendicular to the shaft) and substantial axial loads (parallel to the shaft) in both directions. The larger internal clearances (C3, C4, C5) are vital for managing the heat generated under heavy loads, preventing preloading due to thermal expansion.

- Maximum Type: The increased number of balls directly translates to a larger contact area for distributing radial loads. However, the presence of filling slots makes them less suitable for applications with high axial loads, as the balls can “fall” into these slots under excessive axial force. They excel where purely high radial load capacity is paramount.

- Sealed and Shielded: The presence of seals or shields dictates the bearing’s environmental resilience and speed capabilities.

- Shielded (ZZ): Feature non-contact metal shields that prevent larger particles from entering while allowing for higher speeds due to minimal friction.

- Sealed (RS, 2RS): Utilize contact rubber seals that provide superior protection against fine dust, moisture, and contaminants, but typically result in slightly higher friction and lower limiting speeds compared to open or shielded types. They are pre-lubricated for life in many applications.

- Hybrid (Ceramic Balls): Ceramic balls are significantly harder, lighter, and smoother than steel balls. This results in reduced friction, less heat generation, higher permissible speeds, and often longer lifespan in heavy-duty applications. They are also non-conductive, making them suitable for electric motors or generators.

Proper alignment is crucial for all types of Single Row Deep Groove Ball Bearings – Heavy Duty to ensure optimal performance and prevent premature wear, although some designs can tolerate minor misalignments.

What Industries Use Single Row Deep Groove Ball Bearings – Heavy Duty?

Industries requiring robust and reliable bearing solutions for heavy machinery and continuous operation extensively use Single Row Deep Groove Ball Bearings – Heavy Duty. These include:

- Automotive & Heavy Duty Vehicles: For trucks, buses, construction vehicles, and heavy machinery, particularly in transmissions, axles, and wheel hubs.

- Agriculture: In tractors, harvesters, and other farm equipment that operate in challenging conditions with heavy loads.

- Construction & Earthmoving: Essential in excavators, loaders, dozers, and cranes where components endure high stress and shock.

- Mining & Aggregates: For conveyor systems, crushers, screens, and other heavy equipment processing raw materials.

- Steel & Metal Processing: In rolling mills, presses, and other machinery handling heavy metal products at high temperatures.

- Manufacturing & Industrial Automation: In heavy industrial robots, large machine tools, and manufacturing lines requiring precise and durable motion.

- Energy Sector: Wind turbines, large pumps, and generators rely on heavy-duty bearings for reliable power generation.

Buy Genuine Single Row Deep Groove Ball Bearings – Heavy Duty.

When your operations depend on reliable performance, choosing genuine Single Row Deep Groove Ball Bearings – Heavy Duty is paramount. At www.bearings.co.th, we are committed to providing only authentic products that meet stringent quality standards. Investing in genuine bearings ensures optimal performance, extended lifespan, and reduced downtime for your critical machinery. Explore our comprehensive range and make a confident choice for durability and efficiency.