Basic Dimensions | Design |

||||||||

|---|---|---|---|---|---|---|---|---|---|

d (mm) | D (mm) | Df (mm) | B (mm) | Bf (mm) | Open | Flange Open | Shields | Flange Shields | Seals |

10 | 15 | 16.5 | 3 | 0.8 | 6700 | F 6700 | |||

10 | 15 | 16.5 | 4 | 0.8 | F 6700 ZZ | ||||

10 | 19 | 21 | 5 | 1 | 6800 | F 6800 | ZZ | F 6800 ZZ | 2RS |

10 | 19 | 21 | 7 | 1.5 | 63800 | F 63800 | ZZ | F 63800 ZZ | 2RS |

10 | 22 | 25 | 6 | 1.5 | 6900 | F 6900 | ZZ | F 6900 ZZ | 2RS |

10 | 26 | 8 | 6000 | ZZ | 2RS |

||||

10 | 30 | 9 | 6200 | ZZ | 2RS |

||||

10 | 35 | 11 | 6300 | ZZ | 2RS |

||||

12 | 18 | 19.5 | 4 | 0.8 | 6701 | F 6701 | ZZ | F 6701 ZZ | 2RS |

12 | 21 | 23.0 | 5 | 1.1 | 6801 | F 6801 | ZZ | F 6801 ZZ | 2RS |

12 | 21 | 23.0 | 7 | 1.5 | 63801 | F 63801 | ZZ | F 63801 ZZ | 2RS |

12 | 24 | 26.5 | 6 | 1.5 | 6901 | F 6901 | ZZ | F 6901 ZZ | 2RS |

12 | 28 | 8 | 6001 | ZZ | 2RS |

||||

12 | 32 | 10 | 6201 | ZZ | 2RS |

||||

12 | 37 | 12 | 6301 | ZZ | 2RS |

||||

15 | 21 | 22.5 | 4 | 0.8 | 6702 | F 6702 | ZZ | F 6702 ZZ | 2RS |

15 | 24 | 26.0 | 5 | 1.1 | 6802 | F 6802 | ZZ | F 6802 ZZ | 2RS |

15 | 24 | 26.0 | 7 | 1.5 | 63802 | F 63802 | ZZ | F 63802 ZZ | 2RS |

15 | 28 | 30.5 | 7 | 1.5 | 6902 | F 6902 | ZZ | F 6902 ZZ | 2RS |

15 | 32 | 9 | 6002 | ZZ | 2RS |

||||

15 | 35 | 11 | 6202 | ZZ | 2RS |

||||

15 | 42 | 13 | 6302 | ZZ | 2RS |

||||

17 | 23 | 24.5 | 4 | 0.8 | 6703 | F 6703 | ZZ | F 6703 ZZ | 2RS |

17 | 26 | 28.0 | 5 | 1.1 | 6803 | F 6803 | ZZ | F 6803 ZZ | 2RS |

17 | 26 | 28.0 | 7 | 1.5 | 63803 | F 63803 | ZZ | F 63803 ZZ | 2RS |

17 | 30 | 32.5 | 7 | 1.5 | 6903 | F 6903 | ZZ | F 6903 ZZ | 2RS |

17 | 35 | 10 | 6003 | ZZ | 2RS |

||||

17 | 40 | 12 | 6203 | ZZ | 2RS |

||||

17 | 47 | 14 | 6303 | ZZ | 2RS |

||||

20 | 27 | 28.5 | 4 | 0.8 | 6704 | F 6704 | ZZ | F 6704 ZZ | 2RS |

20 | 32 | 35.0 | 7 | 1.5 | 6804 | F 6804 | ZZ | F 6804 ZZ | 2RS |

20 | 32 | 35.0 | 10 | 2.0 | 63804 | F 63804 | ZZ | F 63804 ZZ | 2RS |

20 | 37 | 40.0 | 9 | 2.0 | 6904 | F 6904 | ZZ | F 6904 ZZ | 2RS |

20 | 42 | 12 | 6004 | ZZ | 2RS |

||||

20 | 47 | 14 | 6204 | ZZ | 2RS |

||||

20 | 52 | 15 | 6304 | ZZ | 2RS |

||||

25 | 32 | 34.0 | 4 | 1.0 | 6705 | F 6705 | 2RS |

||

25 | 37 | 40.0 | 7 | 1.5 | 6805 | F 6805 | ZZ | F 6805 ZZ | 2RS |

25 | 37 | 40.0 | 10 | 2.0 | 63805 | F 63805 | ZZ | F 63805 ZZ | 2RS |

25 | 42 | 45.0 | 9 | 2.0 | 6905 | F 6905 | ZZ | F 6905 ZZ | 2RS |

25 | 47 | 12 | 6005 | ZZ | 2RS |

||||

25 | 52 | 15 | 6205 | ZZ | 2RS |

||||

25 | 62 | 17 | 6305 | ZZ | 2RS |

||||

30 | 37 | 39.0 | 4 | 1.0 | 6706 | F 6706 | |||

30 | 42 | 45.0 | 7 | 1.5 | 6806 | F 6806 | ZZ | F 6806 ZZ | 2RS |

30 | 42 | 45.0 | 10 | 2.0 | 63806 | F 63806 | ZZ | F 63806 ZZ | 2RS |

30 | 47 | 50.0 | 9 | 2.0 | 6906 | F 6906 | ZZ | F 6906 ZZ | 2RS |

30 | 55 | 13 | 6006 | ZZ | 2RS |

||||

30 | 62 | 16 | 6206 | ZZ | 2RS |

||||

30 | 72 | 19 | 6306 | ZZ | 2RS |

||||

35 | 44 | 5 | 6707 | 2RS |

|||||

35 | 47 | 50.0 | 7 | 1.5 | 6807 | F 6807 | ZZ | F 6807 ZZ | 2RS |

35 | 55 | 58.0 | 10 | 2.5 | 6907 | F 6907 | ZZ | F 6907 ZZ | 2RS |

35 | 62 | 14 | 6007 | ZZ | 2RS |

||||

35 | 72 | 17 | 6207 | ZZ | 2RS |

||||

35 | 80 | 21 | 6307 | ZZ | 2RS |

||||

40 | 50 | 6 | 6708 | 2RS |

|||||

40 | 52 | 55.0 | 7 | 1.5 | 6808 | F 6808 | ZZ | F 6808 ZZ | 2RS |

40 | 62 | 65.0 | 12 | 2.5 | 6908 | F 6908 | ZZ | F 6908 ZZ | 2RS |

40 | 68 | 15 | 6008 | ZZ | 2RS |

||||

40 | 80 | 18 | 6208 | ZZ | 2RS |

||||

45 | 55 | 6 | 6709 | 2RS |

|||||

45 | 58 | 61.0 | 7 | 1.5 | 6809 | F 6809 | ZZ | F 6809 ZZ | 2RS |

45 | 68 | 71.0 | 12 | 2.5 | 6909 | F 6909 | ZZ | F 6909 ZZ | 2RS |

45 | 75 | 16 | 6009 | ZZ | 2RS |

||||

45 | 85 | 19 | 6209 | ZZ | 2RS |

||||

50 | 62 | 6 | 6710 | 2RS |

|||||

50 | 65 | 68.0 | 7 | 1.5 | 6810 | F 6810 | ZZ | F 6810 ZZ | 2RS |

50 | 72 | 75.0 | 12 | 2.5 | 6910 | F 6910 | ZZ | F 6910 ZZ | 2RS |

50 | 80 | 16 | 6010 | ZZ | 2RS |

||||

50 | 90 | 20 | 6210 | ZZ | 2RS |

||||

55 | 72 | 9 | 6811 | ZZ | 2RS |

||||

55 | 80 | 13 | 6911 | ZZ | 2RS |

||||

60 | 78 | 10 | 6812 | ZZ | 2RS |

||||

60 | 85 | 13 | 6912 | ZZ | 2RS |

||||

65 | 85 | 10 | 6813 | ZZ | 2RS |

||||

65 | 90 | 13 | 6913 | ZZ | 2RS |

||||

70 | 90 | 10 | 6814 | ZZ | 2RS |

||||

70 | 100 | 16 | 6914 | ZZ | 2RS |

||||

75 | 95 | 10 | 6815 | ZZ | 2RS |

||||

75 | 105 | 16 | 6915 | ZZ | 2RS |

||||

80 | 100 | 10 | 6816 | ZZ | 2RS |

||||

80 | 110 | 16 | 6916 | ZZ | 2RS |

||||

85 | 110 | 13 | 6817 | ZZ | 2RS |

||||

85 | 120 | 18 | 6917 | ZZ | 2RS |

||||

90 | 115 | 13 | 6818 | ZZ | 2RS |

||||

90 | 125 | 18 | 6918 | ZZ | 2RS |

||||

Stainless Steel Single Row Deep Groove Ball Bearings

Discover the exceptional performance and durability of Stainless Steel Single Row Deep Groove Ball Bearings, designed for demanding environments where corrosion resistance and reliability are paramount. At Bearings Specialist Co., Ltd. (www.bearings.co.th), we provide a comprehensive range of these essential components, ensuring your machinery operates smoothly and efficiently.

What are Stainless Steel Single Row Deep Groove Ball Bearings?

Stainless Steel Single Row Deep Groove Ball Bearings are a type of rolling-element bearing that utilizes stainless steel for its components, offering superior resistance to corrosion, moisture, and chemical exposure compared to standard chrome steel bearings. They consist of an inner and outer ring with a single row of balls, a cage to space the balls, and deep raceway grooves that allow them to accommodate both radial and axial loads. Their simple design, high speed capability, and robust construction make them one of the most widely used bearing types across various industries.

Applications for Stainless Steel Single Row Deep Groove Ball Bearings

The inherent corrosion resistance of Stainless Steel Single Row Deep Groove Ball Bearings makes them ideal for applications in:

- Food and Beverage Processing: Conveyors, mixers, bottling lines, and other equipment exposed to washing down procedures or corrosive ingredients.

- Medical and Pharmaceutical Equipment: Sterilizers, dental equipment, laboratory instruments, and machinery requiring sterile environments.

- Marine and Offshore Applications: Boat engines, fishing gear, and equipment exposed to saltwater and harsh weather conditions.

- Chemical Processing: Pumps, agitators, and mixing equipment handling corrosive chemicals.

- Textile Industry: Machinery operating in humid or wet conditions.

- Automotive: Certain areas exposed to moisture or contaminants.

- Agriculture: Equipment operating in damp or outdoor environments.

- General Industrial Machinery: Where regular cleaning or exposure to corrosive elements is a factor.

Types of Stainless Steel Single Row Deep Groove Ball Bearings

These bearings come in various configurations to suit specific needs:

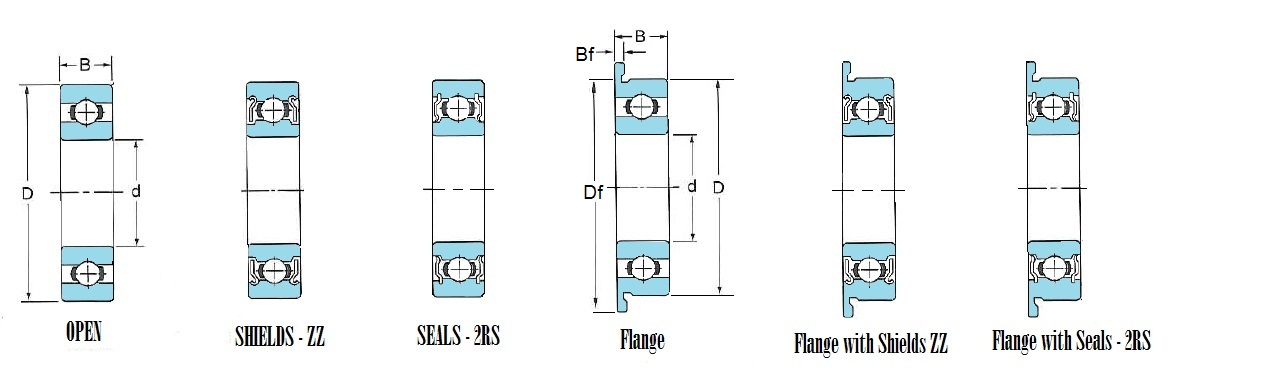

- Open Bearings: Without seals or shields, allowing for easy lubrication and visual inspection. Suitable for clean environments.

- Shielded Bearings (ZZ/2Z): Equipped with metal shields on both sides to prevent the ingress of larger contaminants while allowing some grease retention.

- Sealed Bearings (2RS/2RSR): Feature rubber seals on both sides, providing excellent protection against both solid contaminants and liquids, and ensuring superior grease retention. Ideal for dirty or wet environments.

- With Snap Ring Groove (N): Have a groove on the outer ring for easy axial positioning within a housing.

- With Snap Ring (NR): Include a snap ring in the groove for secure axial retention.

Mechanics of Stainless Steel Single Row Deep Groove Ball Bearings

The fundamental mechanics involve the rolling elements (balls) reducing friction between the rotating and stationary parts. The deep raceway grooves in both the inner and outer rings allow for a large contact area with the balls, enabling the bearing to support significant radial loads and moderate axial loads in both directions. The cage maintains the separation of the balls, ensuring even load distribution and smooth operation. In Stainless Steel Single Row Deep Groove Ball Bearings, the stainless steel material ensures that these mechanical properties are maintained even in corrosive conditions, preventing material degradation that could lead to increased friction, premature wear, and ultimately, bearing failure.

Industries That Use Stainless Steel Single Row Deep Groove Ball Bearings

Beyond the specific applications, these bearings are critical in industries such as:

- Manufacturing

- Food Processing

- Marine

- Medical

- Chemical

- Textile

- Agricultural

- Automotive (specific components)

- Packaging

Buy Genuine Stainless Steel Single Row Deep Groove Ball Bearings

For reliable performance and genuine products, trust Bearings Specialist Co., Ltd. (www.bearings.co.th). We are an authorized distributor of world-renowned brands, ensuring you receive authentic Stainless Steel Single Row Deep Groove Ball Bearings with full manufacturer warranty and support.

Product Information: Single Row Deep Groove Ball Bearings – Metric Size

Our range includes comprehensive metric sizes of Single Row Deep Groove Ball Bearings, featuring standard dimensions (d – bore diameter, D – outer diameter, B – width) as per ISO standards. These bearings are available in various series (e.g., 6000, 6200, 6300, 6800, 6900 series) to meet diverse load and space requirements. Our products, including Stainless Steel Single Row Deep Groove Ball Bearings, are designed for precision, durability, and high-speed operation.