Basic Dimensions | Design |

||||||

|---|---|---|---|---|---|---|---|

d (inch) | D (inch) | B (inch) | B1 (inch) | Reference Number | Open | Shields | Seals |

0.1250 | 0.3750 | 0.1562 | 0.1562 | R 2 | R 2 | ZZ | 2RS |

0.1250 | 0.5000 | 0.1719 | 0.1719 | R 2A | R 2A | R 2AZZ | |

0.1562 | 0.3125 | 0.1094 | 0.1250 | RI 5532 | R 155 | R 155ZZS | |

0.1875 | 0.3125 | 0.1094 | 0.1250 | RI 5632 | R 156 | R 156ZZS | |

0.1875 | 0.3750 | 0.1250 | 0.1250 | RI 6632 | R 166 | R 166ZZS | |

0.1875 | 0.5000 | 0.1562 | 0.1960 | R 3 | R 3 | ZZ | 2RS |

0.1875 | 0.6250 | 0.1960 | 0.1960 | R 3A | R 3A | R 3AZZ | 2RS |

0.2500 | 0.3750 | 0.1250 | 0.1250 | RI 614 | R 168 | R 168ZZS | |

0.2500 | 0.5000 | 0.1250 | 0.1875 | RI 814 | R 188 | R 188ZZ | 2RS |

0.2500 | 0.6250 | 0.1960 | 0.1960 | R 4 | R 4 | ZZ | 2RS |

0.2500 | 0.7500 | 0.2188 | 0.2812 | R 4A | R 4A | ZZ | 2RS |

0.3125 | 0.5000 | 0.1562 | 0.1562 | RI 8516 | R 1810 | ZZ | |

0.375 | 0.8750 | 0.2188 | 0.2512 | RI 1438 | R 6 | ZZ | 2RS |

0.5000 | 1.1250 | 0.2500 | 0.3125 | RI 1812 | R8 | ZZ | 2RS |

0.5000 | 1.3125 | 0.3750 | LJ 1/2 | RLS 4 | ZZ | 2RS |

|

0.5000 | 1.6250 | 0.6250 | MJ 1/2 | RMS 4 | ZZ | 2RS |

|

0.6250 | 1.3750 | 0.2812 | 0.4380 | EE 5 | R 10 | ZZ | 2RS |

0.6250 | 1.5625 | 0.4375 | LJ 5/8 | RLS 5 | ZZ | 2RS |

|

0.6250 | 1.8125 | 0.6250 | MJ 5/8 | RMS 5 | ZZ | 2RS |

|

0.7500 | 1.6250 | 0.3125 | 0.4375 | EE 6 | R 12 | ZZ | 2RS |

0.7500 | 1.8750 | 0.5625 | LJ 3/4 | RLS 6 | ZZ | 2RS |

|

0.7500 | 2.0000 | 0.6875 | MJ 3/4 | RMS 4 | ZZ | 2RS |

|

0.8750 | 2.0000 | 0.5625 | LJ 78 | RLS 7 | ZZ | 2RS |

|

0.8750 | 2.2500 | 0.6875 | MJ 7/8 | RMS 7 | ZZ | 2RS |

|

1.0000 | 2.2500 | 0.6250 | LJ 1 | RLS 8 | ZZ | 2RS |

|

1.0000 | 2.5000 | 0.7500 | MJ 1 | RMS 8 | ZZ | 2RS |

|

1.1250 | 2.5000 | 0.6250 | LJ 1.1/8 | RLS 9 | ZZ | 2RS |

|

1.1250 | 2.8125 | 0.8125 | MJ 1.1/8 | RMS 9 | ZZ | 2RS |

|

1.2500 | 2.7500 | 0.6875 | LJ 1.1/4 | RLS 10 | ZZ | 2RS |

|

1.2500 | 3.1250 | 0.8750 | MJ 1.1/4 | RMS 10 | ZZ | 2RS |

|

1.3750 | 3.0000 | 0.6875 | LJ 1.3/8 | RLS 11 | ZZ | 2RS |

|

1.3750 | 3.5000 | 0.8750 | MJ 1.3/8 | RMS 11 | ZZ | 2RS |

|

1.5000 | 3.2500 | 0.7500 | LJ 1.1/2 | RLS 12 | ZZ | 2RS |

|

1.5000 | 3.7500 | 0.9375 | MJ 1.1/2 | RMS 12 | ZZ | 2RS |

|

1.6250 | 3.5000 | 0.7500 | LJ 1.5/8 | RLS 13 | ZZ | 2RS |

|

1.6250 | 4.0000 | 0.9375 | MJ 1.5/8 | RMS 13 | ZZ | 2RS |

|

1.7500 | 3.7500 | 0.8125 | LJ 1.3/4 | RLS 14 | ZZ | 2RS |

|

1.7500 | 4.2500 | 1.0625 | MJ 1.3/4 | RMS 14 | ZZ | 2RS |

|

1.8750 | 4.0000 | 0.8125 | LJ 1.7/8 | RLS 15 | ZZ | 2RS |

|

1.8750 | 4.5000 | 1.0625 | MJ 1.7/8 | RMS 15 | ZZ | 2RS |

|

2.0000 | 4.0000 | 0.8125 | LJ 2 | RLS 16 | ZZ | 2RS |

|

2.0000 | 4.5000 | 1.0625 | MJ 2 | RMS 16 | ZZ | 2RS |

|

2.2500 | 4.5000 | 0.8750 | LJ 2.1/4 | RLS 18 | |||

2.2500 | 5.0000 | 1.2500 | MJ 2.1/4 | RMS 18 | |||

2.5000 | 5.0000 | 0.9375 | LJ 2.1/2 | RLS 20 | |||

2.5000 | 5.5000 | 1.2500 | MJ 2.1/2 | RMS 20 | |||

2.7500 | 5.2500 | 0.9375 | LJ 2.3/4 | RLS 22 | |||

2.7500 | 6.2500 | 1.3750 | MJ 2.3/4 | RMS 22 | |||

3.0000 | 5.7500 | 1.0625 | LJ 3 | RLS 24 | |||

3.0000 | 7.0000 | 1.5625 | MJ 3 | RMS 24 | |||

3.2500 | 6.0000 | 1.0625 | LJ 3.1/4 | RLS 26 | |||

3.2500 | 7.5000 | 1.5625 | MJ 3.1/4 | RMS 26 | |||

3.5000 | 6.5000 | 1.1250 | LJ 3.1/2 | RLS 28 | |||

3.5000 | 8.1250 | 1.7500 | MJ 3.1/2 | RMS 28 | |||

3.7500 | 6.7500 | 1.1250 | LJ 3.3/4 | RLS 30 | |||

3.7500 | 8.2500 | 1.7500 | MJ 3.3/4 | RMS 30 | |||

4.0000 | 7.2500 | 1.2500 | LJ 4 | RLS 32 | |||

4.0000 | 8.5000 | 1.7500 | MJ 4 | RMS 32 | |||

4.2500 | 7.5000 | 1.2500 | LJ 4.1/4 | RLS 34 | |||

4.2500 | 8.7500 | 1.7500 | MJ 4.1/4 | RMS 34 | |||

4.5000 | 8.0000 | 1.3125 | LJ 4.1/2 | RLS 36 | |||

4.5000 | 9.3750 | 2.0000 | MJ 4.1/2 | RMS 36 | |||

4.7500 | 8.2500 | 1.3125 | LJ 4.3/4 | RLS 38 | |||

4.7500 | 10.0000 | 2.0000 | MJ 4.3/4 | RMS 38 | |||

5.0000 | 9.0000 | 1.3750 | LJ 5 | RLS 40 | |||

5.0000 | 10.0000 | 2.0000 | MJ 5 | RMS 40 | |||

5.5000 | 9.5000 | 1.3750 | LJ 5.1/2 | RLS 44 | |||

5.5000 | 11.0000 | 2.0000 | MJ 5.1/2 | RMS 44M | |||

6.0000 | 10.5000 | 1.5625 | LJ 6 | RLS 48 | |||

6.5000 | 11.0000 | 1.5625 | LJ 6.1/2 | RLS 52 | |||

7.0000 | 12.0000 | 1.7500 | LJ 7 | RLS 56M | |||

7.5000 | 12.5000 | 1.7500 | LJ 7.1/2 | RLS 60M | |||

8.0000 | 13.0000 | 1.7500 | LJ 8 | RLS 64M | |||

9.0000 | 14.5000 | 2.0000 | LJ 9 | RLS 72M | |||

10.0000 | 15.7500 | 2.0000 | LJ 10 | RLS 80M | |||

11.5000 | 18.0000 | 2.3750 | |||||

Single Row Deep Groove Ball Bearings – Inch Size

Unlock Precision and Durability with Single Row Deep Groove Ball Bearings – Inch Size

When it comes to the smooth and efficient operation of machinery, the right bearing makes all the difference. Single Row Deep Groove Ball Bearings – Inch Size are fundamental components, engineered to handle both radial and axial loads with exceptional performance. These versatile bearings are characterized by their deep raceway grooves and close conformity between the raceways and balls, which enables them to sustain significant loads and high speeds. Designed to precise inch dimensions, they are a preferred choice for a vast array of industrial and commercial applications where American or Imperial standards are prevalent. Understanding the critical role of Single Row Deep Groove Ball Bearings – Inch Size is key to ensuring optimal mechanical function and longevity.

Applications of Single Row Deep Groove Ball Bearings – Inch Size

The versatility of Single Row Deep Groove Ball Bearings – Inch Size makes them indispensable across countless sectors. Their ability to handle diverse load conditions and operate at high speeds makes them ideal for:

- Electric Motors: Ensuring smooth rotation of motor shafts, reducing friction and extending motor life.

- Pumps: Facilitating efficient fluid movement in various pumping systems.

- Automotive Components: Crucial in wheel hubs, transmissions, and accessory drives for reliable vehicle performance.

- Agricultural Machinery: Withstanding demanding conditions in tractors, harvesters, and irrigation equipment.

- Conveyors and Material Handling Systems: Supporting precise and continuous movement of goods.

- Gearboxes: Enabling seamless power transmission and reducing wear.

- Household Appliances: Found in washing machines, vacuum cleaners, and more, for quiet and efficient operation.

- Power Tools: Providing the necessary support for high-speed rotation in drills, saws, and grinders.

- Medical Equipment: Ensuring precision and reliability in sensitive devices.

- Textile Machinery: Supporting high-speed spindles and rollers for consistent fabric production.

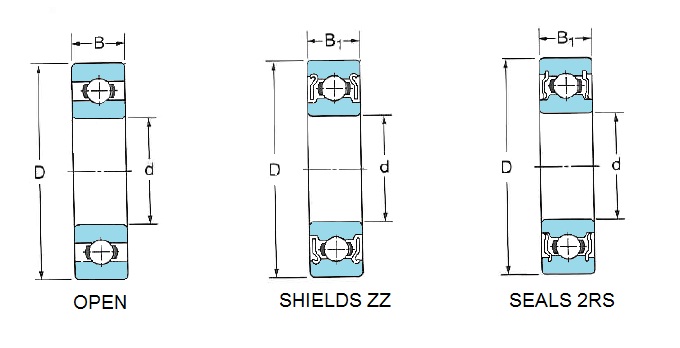

Types of Single Row Deep Groove Ball Bearings – Inch Size

While the core design remains consistent, Single Row Deep Groove Ball Bearings – Inch Size come in various configurations to suit specific operational needs:

- Open Type: These bearings lack seals or shields, making them suitable for applications where lubrication can be easily replenished and contamination is not a significant concern. They offer the lowest friction.

- Shielded (ZZ) Type: Featuring metal shields on both sides, these bearings are protected from larger contaminants while allowing for some lubricant retention. The shields do not contact the inner ring.

- Sealed (2RS) Type: Equipped with contact seals made of synthetic rubber on both sides, these bearings provide superior protection against dust, dirt, and moisture. They also retain lubricant effectively, leading to longer service life in contaminated environments.

- Snap Ring Type: These bearings include a snap ring groove on the outer ring, allowing for easy axial positioning within a housing, simplifying assembly and reducing manufacturing costs.

Mechanics of Different Types of Single Row Deep Groove Ball Bearings – Inch Size

The fundamental mechanics of Single Row Deep Groove Ball Bearings – Inch Size involve the rolling elements (balls) located between an inner and an outer ring, separated by a cage.

- Open Type: The balls roll freely in the raceways, allowing for minimal friction. This design is best for clean environments where the bearing can be regularly lubricated, allowing for maximum speed and efficiency.

- Shielded (ZZ) Type: The non-contact metal shields prevent larger debris from entering the bearing while allowing for a small gap for lubricant to escape or enter. This design provides a balance between protection and reduced friction compared to sealed types. The balls still roll with minimal resistance, and the shields help maintain internal cleanliness to a degree.

- Sealed (2RS) Type: The contact seals create a tighter barrier, significantly reducing the ingress of contaminants and preventing lubricant leakage. While this slightly increases friction compared to open or shielded types, the enhanced protection and reduced maintenance often outweigh this. The balls still roll effectively, but the seals ensure a consistently cleaner internal environment.

- Snap Ring Type: The snap ring simply aids in the mounting and axial location of the bearing. The internal mechanics of rolling are identical to the open, shielded, or sealed variants depending on the specific snap ring bearing type (e.g., 2RSN for a sealed bearing with a snap ring groove).

What Industries Use Single Row Deep Groove Ball Bearings – Inch Size?

The widespread adoption of Single Row Deep Groove Ball Bearings – Inch Size spans a diverse range of industries due to their reliability and performance:

- Manufacturing and Industrial Automation: Used in robotics, CNC machines, and assembly lines for precise motion control.

- Food and Beverage Processing: Essential in conveying systems, packaging machinery, and mixing equipment, often requiring stainless steel variants.

- HVAC Systems: Employed in fans, blowers, and air handling units for smooth and quiet operation.

- Textile Industry: Critical in high-speed spinning, weaving, and finishing machinery.

- Mining and Construction: Found in heavy-duty equipment such as excavators, loaders, and conveyor systems, often requiring robust designs.

- Pulp and Paper: Used in paper machines, debarkers, and other processing equipment.

- Agriculture: Integral to the operation of farm machinery, including tractors, harvesters, and irrigation pumps.

- Automotive Aftermarket: Widely used for replacement parts in various vehicle systems.

Buy Genuine Single Row Deep Groove Ball Bearings – Inch Size from www.bearings.co.th

When selecting bearings for your critical applications, authenticity and quality are paramount. At www.bearings.co.th, we pride ourselves on supplying only genuine Single Row Deep Groove Ball Bearings – Inch Size from world-renowned manufacturers. We understand that counterfeit bearings can lead to premature failure, costly downtime, and even safety hazards. By choosing us, you are guaranteed to receive authentic products that meet rigorous quality standards, ensuring optimal performance and longevity for your machinery. Our extensive product range and expert support make us your trusted partner for all your bearing needs. Visit www.bearings.co.th today to explore our selection and experience the difference of genuine quality.

Product Information and Other Facts

Single Row Deep Groove Ball Bearings – Inch Size are designed for precision and durability. Key characteristics include:

- High Speed Capability: The geometry of the raceways allows for operation at high rotational speeds with minimal heat generation.

- Versatile Load Handling: Capable of supporting both radial loads (perpendicular to the shaft) and axial loads (parallel to the shaft) in both directions.

- Low Friction: Their design minimizes friction, leading to energy efficiency and reduced heat build-up.

- Simple Design: This simplicity contributes to their cost-effectiveness and ease of maintenance.

- Standardized Dimensions: Inch-size bearings adhere to specific imperial dimension series, ensuring interchangeability and ease of integration into existing systems.

- Material: Typically manufactured from high-carbon chromium steel for excellent hardness and wear resistance. Stainless steel variants are available for corrosive environments.

Famous and Reliable Brands for Single Row Deep Groove Ball Bearings – Inch Size

At Bearings Specialist Co., Ltd, we are proud authorized distributors for leading global brands, ensuring you receive the highest quality Single Row Deep Groove Ball Bearings – Inch Size.

Authorized Distributor Brands (Highly Recommended):

- TIMKEN: Renowned for their engineering excellence and robust bearing solutions across various industries.

- NSK: A global leader in bearing manufacturing, known for precision and innovation.

- NIS: Offers a comprehensive range of high-quality bearings for diverse applications.

- MTM: Delivers reliable bearing solutions with a focus on performance and longevity.

Other Reputable Brands (Also widely recognized for quality):

- FAG

- NTN

- KOYO